Refined Technology, Mentech Creates "High end Quality" Magnetic Components.

The new energy industry is rapidly advancing! In this industry, "installed capacity" is an eternal topic. To ensure installation, there is a small component that cannot be ignored, as it is crucial for ensuring the energy-saving, safety, and stability of electronic equipment. This is the magnetic component.

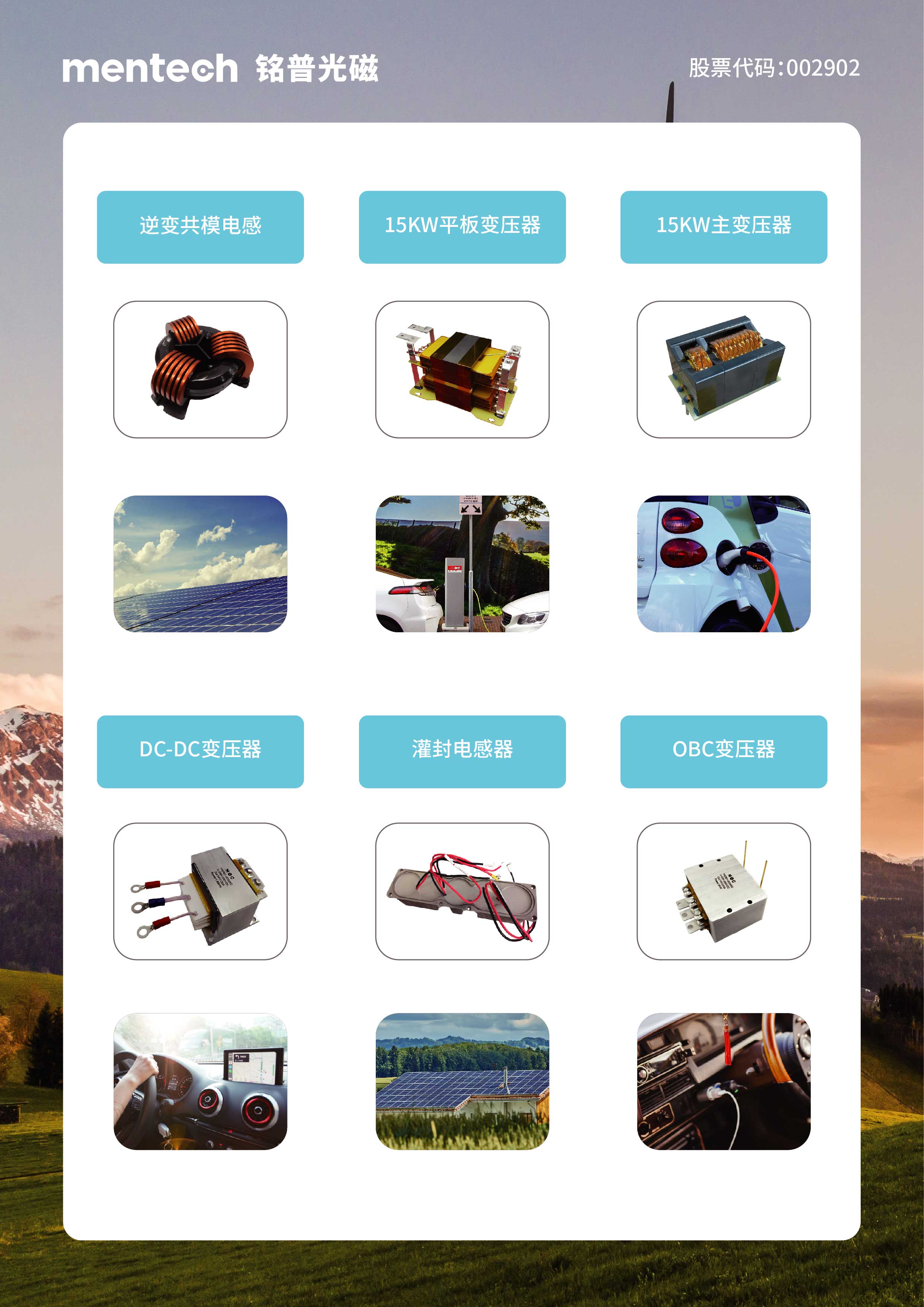

Magnetic components run through various application scenarios such as photovoltaic inverters, energy storage inverters, new energy vehicles, and charging stations, and are an extremely important link in the new energy supply chain.

As a leading manufacturer of magnetic components, Dongguan Mentech Optical & Magnetic Co., Ltd. (hereinafter referred to as "Mentech") has long been engaged in the research and development, production, and sales of high-precision and high-power electronic components. It has a more professional understanding of the magnetic components in the field of new energy segmentation.

Focus on technology to create greater value for customers

Mentech is a high-tech enterprise that focuses on the research and development, production, sales, and service of magnetic components. It is also a renowned leader in the magnetic component industry.

In 2013, Mentech made an important strategic deployments, aiming to expand in the fields of "new energy" and "digitalization", and took the lead in moving from a basic magnetic component supplier to a high-end magnetic component solution provider in the industry. Nowadays, Menrech has formed a diversified product matrix that deeply covers the relevant industry chain.

In a conversation with the reporters from the International Energy Network, Yang Jianmin, the chief engineer of Mentech said, "Making new energy magnetic components, strengthening products and technology is the fundamental point. Mentech's technological research and development not only achieves what customers want, but also maximizes the satisfaction of their differentiated needs.

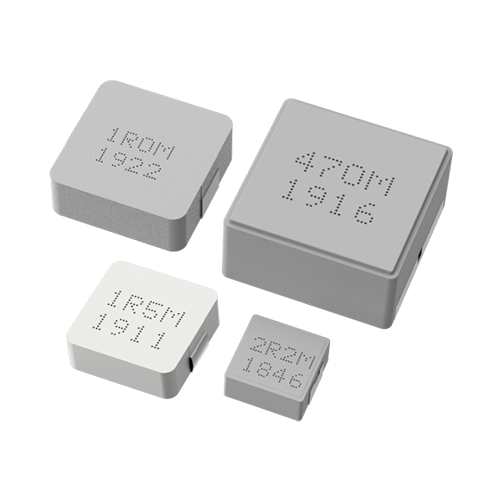

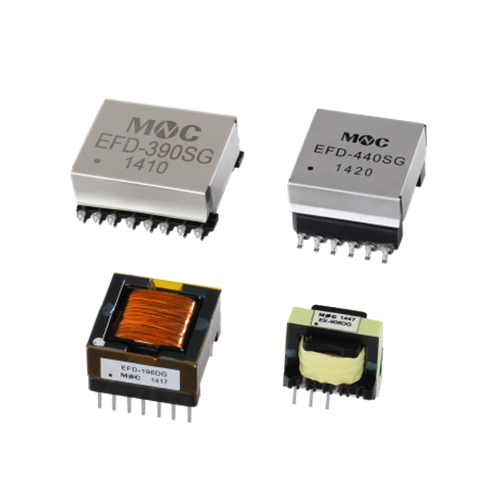

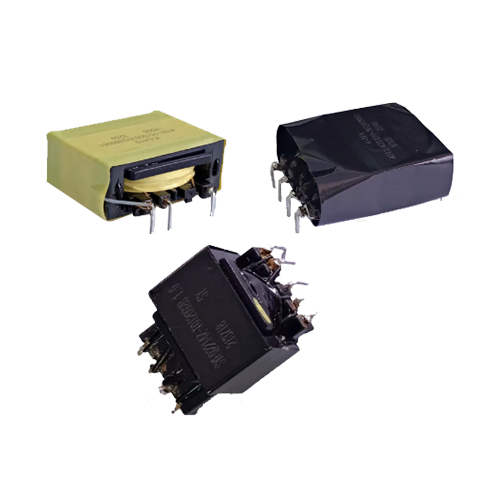

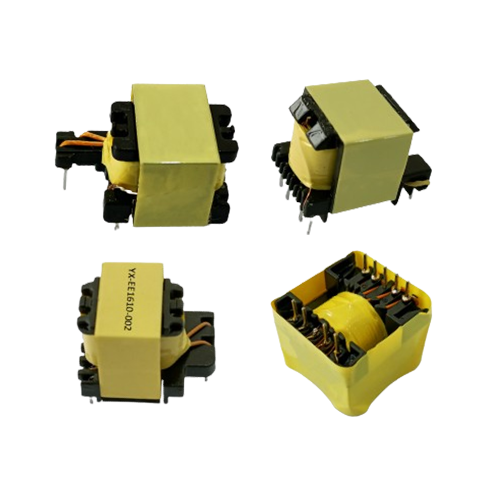

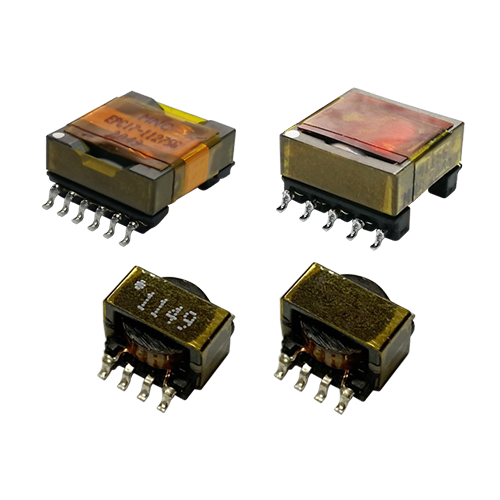

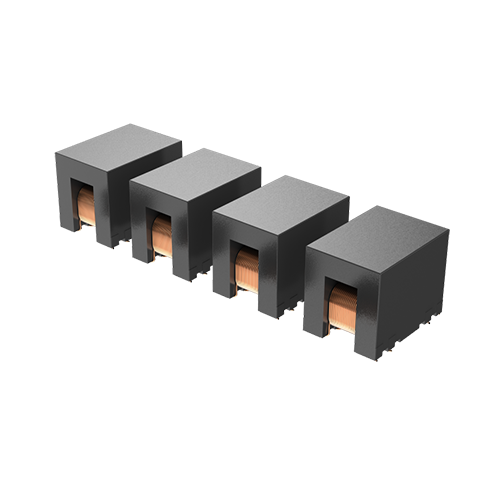

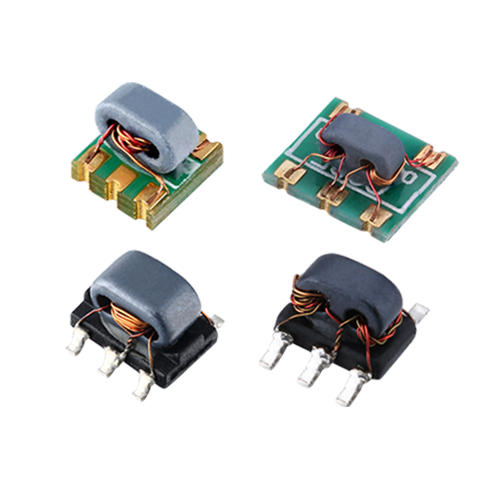

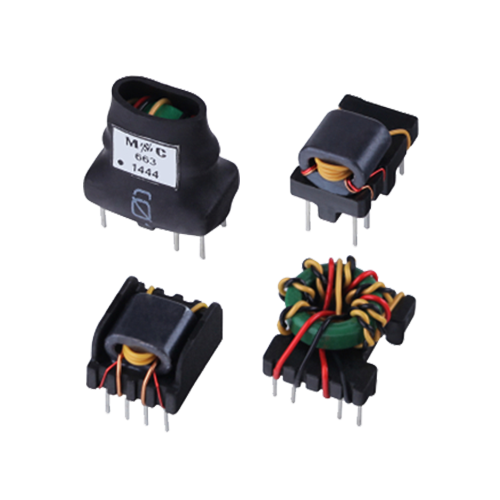

Although magnetic components such as electronic transformers and inductors are only seemingly small components, they play a crucial role in new energy vehicles, photovoltaic inverters, and energy storage inverters.

For the magnetic integration technology widely recognized in the market now, it can reduce comprehensive costs by 5% to 10%. As early as more than 10 years ago, Mentech's magnetic integration technology had mature application cases, and continuously improved and upgraded in the following years.

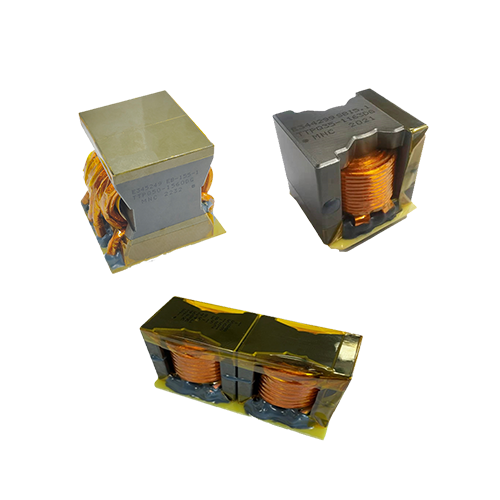

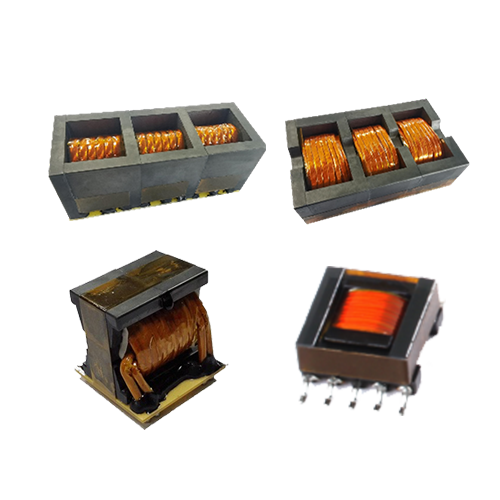

Magnetic integration technology, as the name suggests, is the integration technology of magnetic circuits. “Integrating various functional magnetic components onto complex magnetic core structures to achieve the goals of reducing module size, reducing losses of magnetic element devices and so on.” Yang Jianmin introduced.

Mentech’s Precision Research aims to comprehensively improve product performance and competitiveness by optimizing the design structure and searching for advanced raw materials, while meeting the basic technical needs of customers, and creating greater value for customers.

From the perspective of optimizing the design structure, the inductors and electronic transformers with different magnetic circuits will be integrated together to achieve simplification in structure and volume. In addition, utilizing magnetic leakage as an inductive magnetic circuit synchronously solves the problem of magnetic leakage.

From the view of material optimization, Mentech utilizes its mastery of material characteristics to assemble and integrate ferrite materials with high permeability and metal powder cores with strong DC stacking resistance, which can form higher DC stacking resistance.

Adopting magnetic integration technology not only effectively reduces the overall volume of the product, but also has characteristics such as strong magnetic coupling ability, low electromagnetic interference, high transmission efficiency, convenient production, and strong universality, "said Yang Jianmin. What’s more, for customers, it is more important to improve production efficiency and power density through magnetic integration technology.

Keep improving to meet customers’ needs.

In fact, for manufacturers of magnetic components, everyone faces a common problem, which is that almost all magnetic components are customized and there are basically no standardized products. This also means that the R&D team must meet the differentiated needs of customers.

Yang Jianmin said, "The basic formulas and principles of design are the same, and the software is also the same. However, when designing, using different magnetic cores and structures to adjust parameters will result in thousands of design solutions. Even if the same enterprise uses the same materials and structure, engineers with different design experiences will design different products.

This is the biggest problem faced by the production of magnetic components. Yang Jianmin often ponders how to fully meet customer needs while ensuring product quality and achieving stable supply of magnetic component products in such a situation.

Through exploration, Mentech has gradually embarked on its own path of specialization, that is, based on full participation in customer preliminary design to "standardize" non-standard products as much as possible around product characteristics and application scenarios, and achieve pin-to-pin product development and production manufacturing through processes and quality control.

Not only in product development and design, but also in internal management, Mentech emphasizes standardization and has established a series of "materials selection warehouse" for customers to choose from. “In this way, we have created a standardized solution internally that allows non-standard products to operate in a standardized manner as much as possible, effectively ensuring the production efficiency of the products, "said Yang Jianmin.

In addition to considering electrical and magnetic properties, manufacturability is also crucial in the design of magnetic components. For magnetic component manufacturers, some companies find it difficult and laborious to process due to not participating in the customer's preliminary design plan, resulting in increased costs. Additionally, they cannot achieve automation for mass production, which affects production efficiency and prolongs production cycles.

Furthermore, Mentech has an automated development team, precision machining capabilities, and the ability to develop, design, and produce specialized equipment. This is another key point for it to meet customers’ needs.

For manufacturers of optical storage inverters, product innovation is a highly valued trait by major companys. Mentech not only meets the unique needs of each customer's products with excellent automation and precision processing capabilities, but also ensures high quality and consistency of products through automated production.

Automated production capacity not only brings high quality products, but more importantly, fully guarantees stable supply. Yang Jianmin said, "Stable supply and quality assurance are the foundation of business credit, and improving product automation will reduce a portion of production costs. We are willing to transmit the benefits of this part to customers, achieve value sharing, and assume corporate responsibility.”

Use professional strength to promote the development of industry technology.

Our Strong R&D capabilities and leading technological advantages ensure that we can continue to provide high-quality, reliable, and low-cost products to the market, winning a good market reputation and high-quality customer resources for the company. At present, Mentech has established good product reputation around the world.

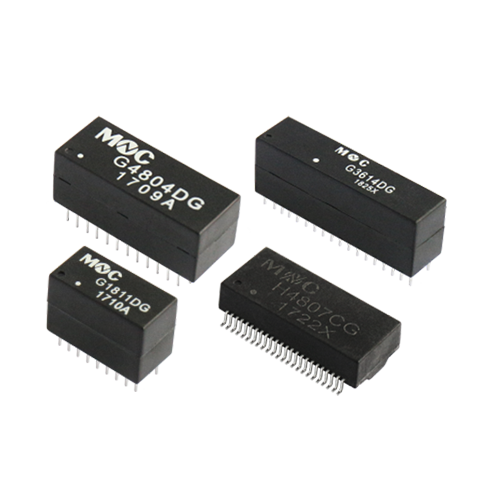

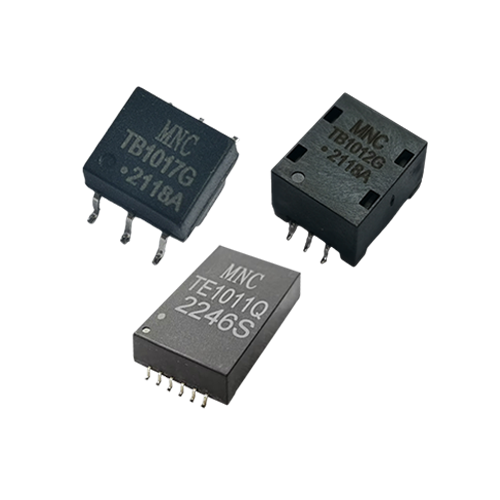

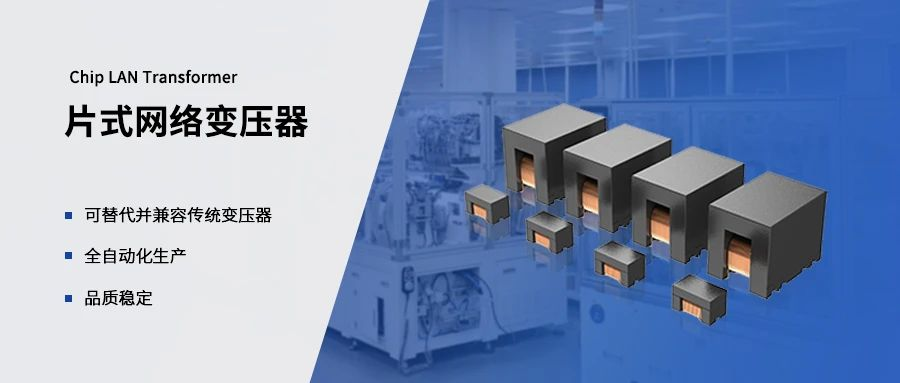

Taking network transformers as an example, Yang Jianmin introduced that Mentech was the first to successfully develop chip network transformers, achieving fully automated mass production of chip network transformers. In addition, it also attaches great importance to intellectual property protection. As of the end of 2022, Mentech and its subsidiaries have 341 valid patents.

At the recently held Intersolar Europe 2023 exhibition, Mentech made a debut with a series of new products, customizing and developing new energy magnetic components, including transformers for micro inverters, inverter inductors, encapsulated inductors, optimizer inductors, high-frequency transformers, etc., which gained great attention in Munich. At the same time, familiarity with international standards has also become an important driving force for Mentech to obtain impressive "transcripts" in the international market.

Therefore, whether in the domestic market or overseas market, Mentech will continue to expand its competitive advantages and enhance its industry influence, committed to providing high-quality and competitive products and comprehensive solutions to global customers, and leading the industry towards continuous transformation and upgrading towards high-end intelligence and green environmental protection.

Mentech Mall

Mentech Mall Group Website

Group Website